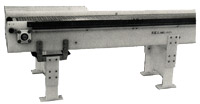

| Dura-Vey™ Model 2400EP Straight Conveyor | |

|---|---|

| Framework: | 3/4 inch thick x 11-3/4 inch deep polypropylene – welded construction |

| Bed: | 3/4 inch thick x between frame dimension with 1/4 inch thick UHMW replaceable bed wear plate. |

| Belt: | Acid resistant polypropylene set 2 inches low in frame. |

| Floor Supports: | Polypropylene, adjustable from 30 inches to 36 inches to top of belt. |

| Drive Sprockets: | Acid resistant 6.4″ pitch diameter. |

| Tail Sprockets: | Acid resistant 6.4″ pitch diameter. |

| Shafts: | 1-1/2 inch square 316 stainless steel. |

| Bearings: | UHMW with Lubra-Tuf™ self-aligning inserts. |

| Fasteners: | Where required – 316 stainless steel. |

| Drive: | End drive completely enclosed by polypropylene cover. |

| Transition Rollers: | 1.90 inch PVC fully lagged. |

| Return Rollers: | 1.90 inch PVC. |

| Motor: | 1/2 H.P. – 230/460 – 3PH 60HZ – TEFC. |

| Belt Speed: | Constant 30 FPM. |

| Capacity: | 100 pounds per linear foot. NOT TO EXCEED belt capacity. |

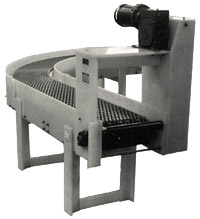

| Dura-Vey™ Model 2410 Curved Conveyor | |||

|---|---|---|---|

| BR: | 9″-10″ | 11″-13″ | 15″-17″ |

| Belt Width: | 7-1/4″ | 10-1/4″ | 13-1/4″ |

| Center Line Radius | 39″ | 39″ | 49″ |

The Ultimate Conveyor System For Acid Environments!

- 100% Polypropylene Framework and Belting Provides Maximum Acid Resistance.

- Welded Construction.

- UHMW Bed Section.

- Overhead Drive Mount Minimizes Acid Exposure.

- Powered Transition Rollers Provide Positive Transfer.

- Positive Case Alignment Through Turns.